- Contact Us

- |

- Jobs

- |

- About Us

- |

- |

-

- Personal information

- Organization

- Quotes

- Address book

- Login

- Don't have an account? Sign-up

Oriented wire shield

- Home

- EMI shielding gaskets solutions

- EMI/IP gasket

- Oriented wire shield

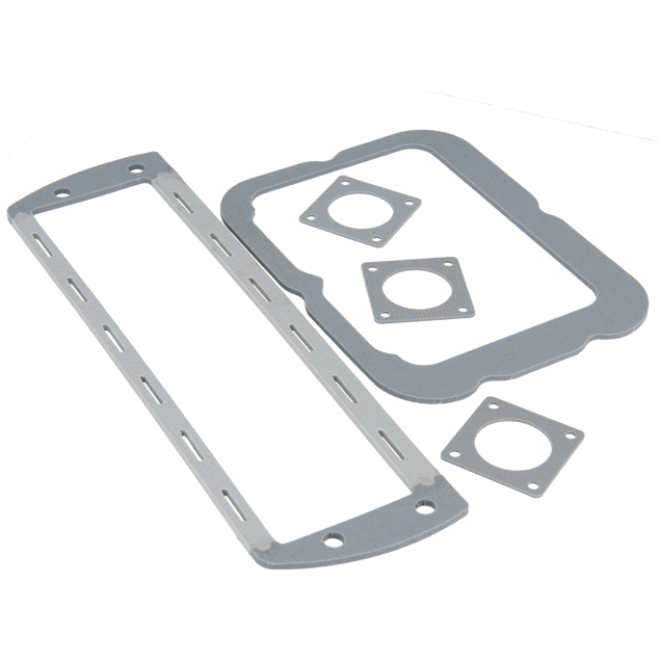

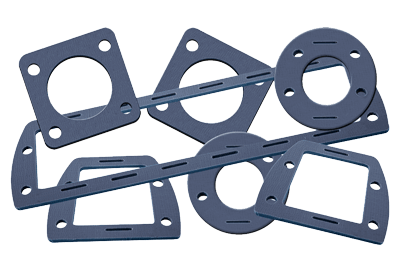

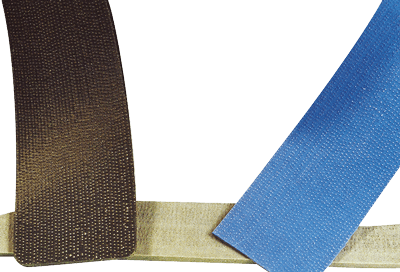

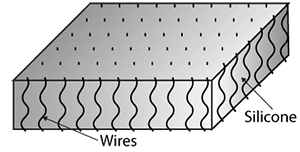

Oriented wire shield 5711 - 5722 is a composite gasket material consisting of a large number of small wires embedded and bonded in solid or sponge silicone or fluorosilicone elastomer for oil resistance.

The wires provide excellent conductivity to establish EMI/RFI shielding.

The material is used in military, industrial and commercial products requiring EMI suppression, grounding or static discharge. It is very suitable for applications where an environmental or pressure seal is required.

The sponge version is used in cases where the joint is very uneven or if lower closure forces or greater compressibility are required.

Dimension

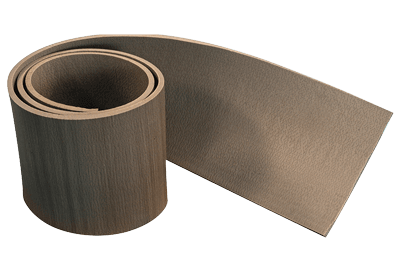

We produce sheets of max. 228 x 900 mm, from which we can then cut gaskets without interruptions. Bigger gaskets can be welded/joined together in order to prevent waste of material.

Custom compositions are available on request, contact us with your a drawing and with the desired dimensions.

Benefits

- Temperatures up to 220 °C

- High shielding performance

- Water sealing up to 10 meters

- Pressure resistant

- Salt spray/chemical resistant

- Fluorosilicone rubber for fuel/oil resistance

- Supplied as sheets, strips or die-cuts

Available thicknesses

0.81, 1.13, 1.38, 1.57, 2.40, 3.18, 3.96, 4.78, 6.35 mm.

Other thicknesses on request.

Shielding performance

Please note : These values are measured under laboratory conditions. Results may vary in other situations; please read our Guarantee.

Technical drawing

Part numbers

| Material | Part number |

|---|---|

| Solid silicone with monel wire | 5711 |

| Solid silicone with aluminium wire | 5712 |

| Solid fluorosilicone with monel wire | 5713 |

| Sponge silicone with monel wire | 5721 |

| Sponge silicone with aluminium wire | 5722 |

Technical specifications

| Material | Solid silicone with monel wire | Solid silicone with aluminium | Solid fluorosilicone with monel wire | Sponge silicone with monel wire | Sponge silicone with aluminium wire |

|---|---|---|---|---|---|

| Part number | 5711 | 5712 | 5713 | 5721 | 5722 |

| Color | Gray | Gray | Blue | Gray | Gray |

| Wire count/ sq. inch | 900 | 900 | 900 | 900 | 900 |

| Compression set | 25% | 25% | 25% | 25% | 25% |

| Closing force (PSI) | 25-100 | 25-100 | 25-100 | 5-50 | 5-50 |

| Fuel/solvent resistant | No | No | Yes | No | No |

| Temperature (°C) | -65/200 | -65/200 | -55/200 | -65/200 | -65/200 |

Technical specifications

| Elastomer | Silicone or fluorosilicone |

|---|---|

| Conductive filler | Monel wire, aluminium wire |

| ROHS compliance | Yes |

| Corrosion resistance | Yes |

| UV resistance | Yes |

| Oil resistance | Fluorosilicone type only |

| Fuel resistance | Fluorosilicone type only |

| IP rating | Yes |

| Shore A | 35-40 |